Simple Steps to Better Quality

KwikTic Work Instructions are a great way to reduce build time and improve quality by putting the right people, on the right tasks at the right time.

KwikTic guides and trains your operators reducing build time, improving yield and eliminating rework.

By going digital with KwikTic, you’ll eliminate cumbersome paper processes, ensure everyone always has current information, improve quality, reduce operator skill set required and much more…

Are you ready to simplify and standardize your documentation?

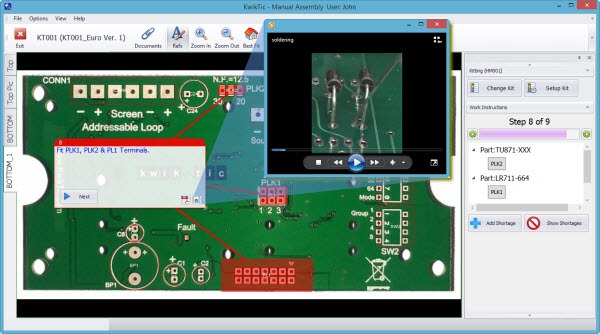

Also use them to collect test results, material used, process conditions.

FLEXIBLE & EFFECTIVE

KwikTic is a digital Work Instructions solution that dramatically reduces the skill level requirement for workers in your production facility.

By building KwikTic Work Instructions into your product assembly process, your organization can optimize efficiencies, improve quality and reduce training time on new products.

SEAMLESS

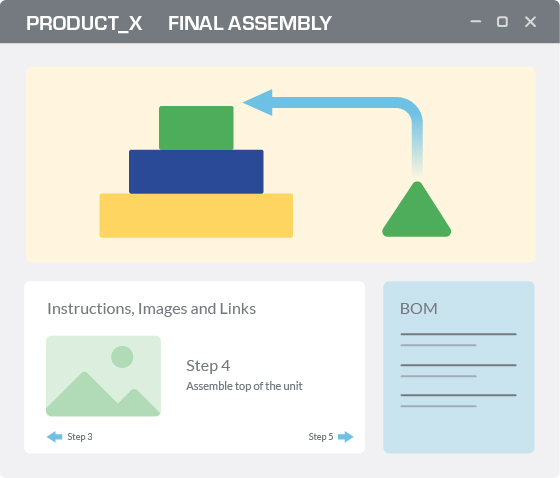

Imagine a world where your staff get the exact step-by-step instructions they need, when they need them, on any device. And imagine if you could seamlessly collect data and measure the results.

SIMPLE

Create, edit and share digital work instructions in minutes. No more printed PDFs or paper, just a clear user-friendly guide that’s ready to use throughout the shopfloor.

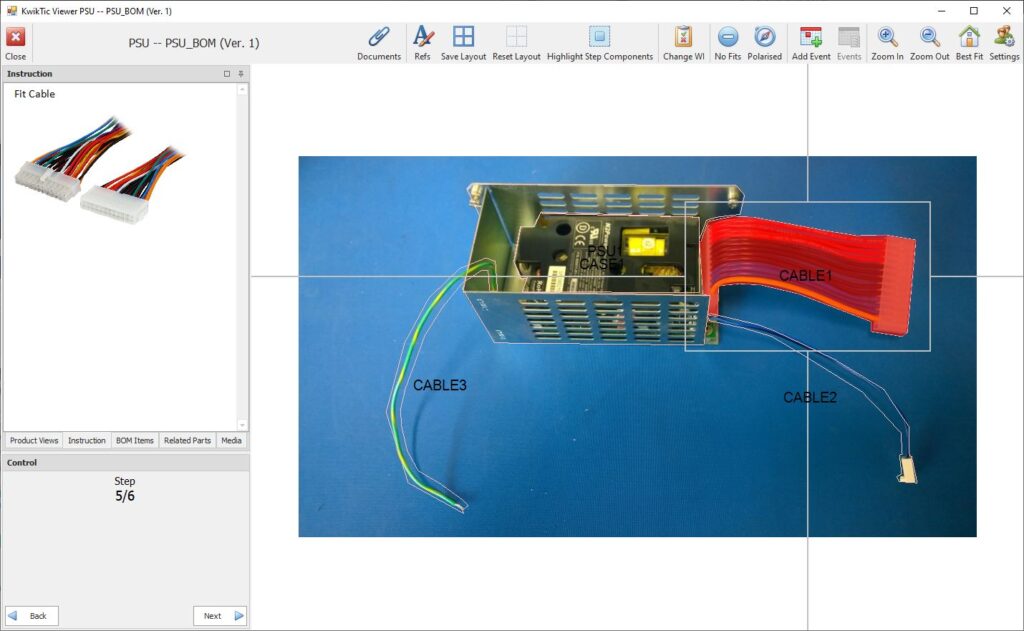

Operators can easily find the correct revision of Instruction for the right process and access it immediately. This can be done by manually choosing the Product then the Work Instruction; Fully automatically by entering the Batch or Serial Number.

Each user can Customise their page layout to suit them.

RELIABLE, CONSISTENT & CONTROLLED

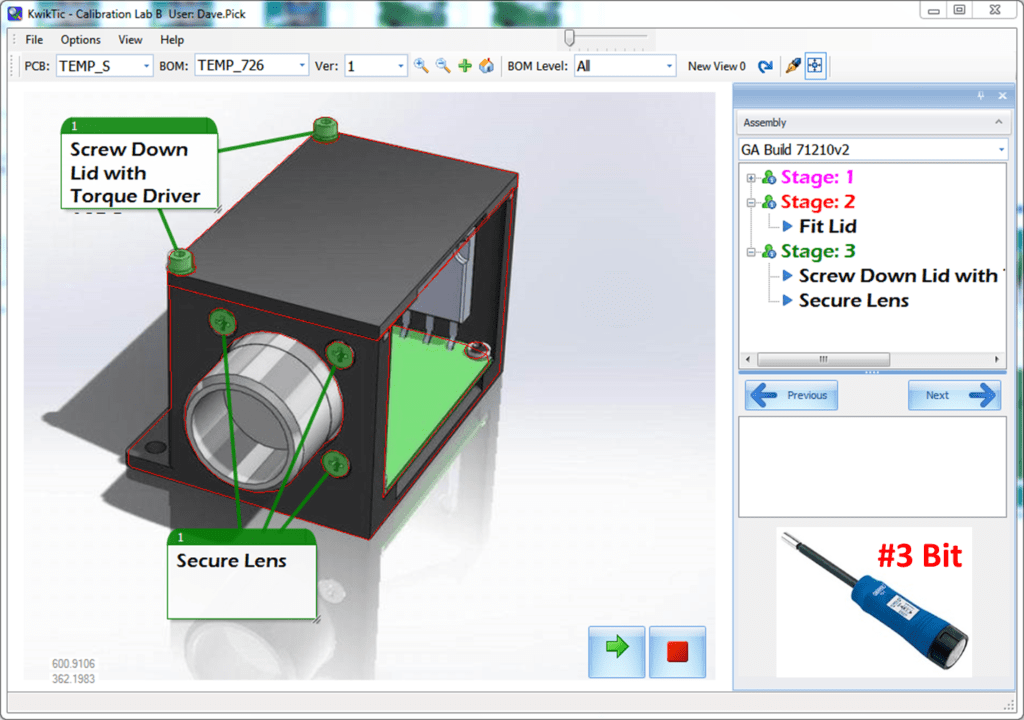

Have you ever questioned how a product should be built? How to use the machine safely and correctly? Do you want to improve your quality and cycle times? Do you want to simplify life, centralise and standardise documentation creation, distribution and revision control? With KwikTic Work Instructions you can.

Eliminate manual work instructions, paper and binders. Replace with a fully interactive electronic format. KwikTic is the tool your company needs to bring the process up-to-date and make it more effective, efficient, and safe.